HOT PRODUCTS

ABOUT US

Since its foundation in 1996. NAEC is committed to technological research, process and procedure of metal prefabrication and installation quality and efficiency with welding as the core subject, as well as research, design, manufacturing, delivery, supervision and operation of informationalized and smart solution.

INTELLIGENT SOLUTIONS

Storage Tank Construction Solution-null

Storage Tank Construction Solution

We began R&D of automatic tank welding machines from year 2001. Now we have different types of tank welding machines for Oil Storage Tank. LNG Tank or Tower. The automatic tank welding machines we developed conform to CE standard. Besides we also developed hydraulic jacking system for top-to-bottom tank construction. Now we have matured whole solutions & equipments for both bottom-to-top and-top-to-bottom tank construction. By our solution, we can help our customer to finish one tank body construction within one month...

Horizontal Shell Fabrication Solution-null

Horizontal Shell Fabrication Solution

Horizontal tank shell is rolled from a steel plate with approximate length 3M. In our design we suggest 3M length sections can be fitted-up to a 12M length shell. And the 12M shell can be extended to required length. We integrated advanced and high efficient fabrication technology such as tandem welding and multi-wire welding into our design, designed machines suitable for different seams welding. Such whole planning and design has been implemented in the offshore fabrication base of CNPC. Our horizontal tank shell fabrication solution covers plate cutting, plate edge milling, shot blasting and painting, plate rolling, longitudinal seam welding, shell fitting-up, pretreatment, circumferential seam welding, shell extension; and non-destructive testing. Our offshore pipe pile/pipe rack fabrication capability suitable for pile rack diameter range from 500mm to 5000mm...

Pipeline Double Joining Solution-null

Pipeline Double Joining Solution

NAEC Pipeline Double Joining One Stop Solution adopts modular design which consist of multiple pipeline beveling stations, pipeline fitting-up and joining stations, and pipeline welding stations. It integrates with roller-bed type conveying system to reduce the dependence of on-site crane equipment. Compared with traditional pipeline construction method, nearly 1/2 welding joints can be fabricated by our Pipeline Double Joining One Stop Solution in advance and then other 1/2 welding joints will be done onsite by all-position welding method. Then the welding quality can be guaranteed. It's also easy to repair...

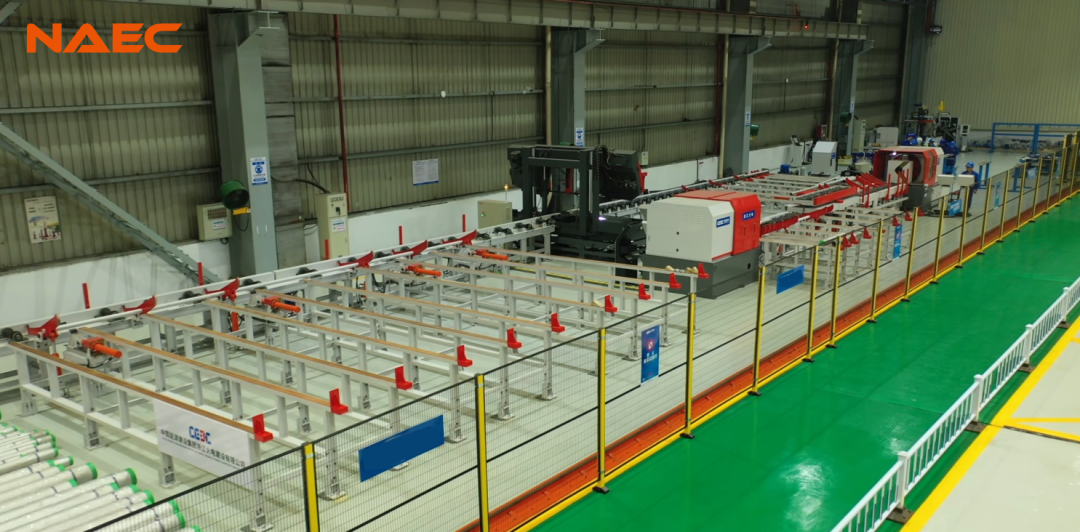

Intelligent Workshop Solution-

Intelligent Workshop Solution

Lean fabrication intelligent workshop is mainly consisted of three core parts, which are lean fabrication management system, lean fabrication design system and lean fabrication production system...

Intelligent Workshop Management System-

Intelligent Workshop Management System

Intelligence serves production, digital drives lean fabrication. The intelligent workshop established by NAEC, is the deep integration and innovation of advanced fabrication technology, information technology and communication technology under the workshop scene, which can improve the effective workshop output, and reduce the fabrication cost. Relied on the advanced technologies including Digital Twin, 5G+AR, Big Data, Artificial Intelligence, Internet of Things, Cloud Computing and Edge Computing etc., we provide digital one-stop solutions which set lean management as core concept to intelligent manufacturing industry such as energy engineering and construction machinery etc., provide intelligent workshop one-stop proposal, intelligent workshop management system and customized management system.

Intelligent Logistic System-

Intelligent Logistic System

Intelligence serves production, digital drives lean fabrication. The intelligent workshop established by NAEC, is the deep integration and innovation of advanced fabrication technology, information technology and communication technology under the workshop scene, which can improve the effective workshop output, and reduce the fabrication cost. Relied on the advanced technologies including Digital Twin, 5G+AR, Big Data, Artificial Intelligence, Internet of Things, Cloud Computing and Edge Computing etc., we provide digital one-stop solutions which set lean management as core concept to intelligent manufacturing industry such as energy engineering and construction machinery etc., provide intelligent workshop one-stop proposal, intelligent workshop management system and customized management system.

Intelligent Manufacturing丨Flexible Automated Excavator Solution-

Intelligent Manufacturing丨Flexible Automated Excavator Solution

Amid the wave of intelligent upgrades in the manufacturing industry, the traditional construction machinery sector is undergoing a profound transformation. As the most representative product in the construction machinery industry, excavators feature ...

lntelligent Pipe Spool Lean Fabrication Solution-null

lntelligent Pipe Spool Lean Fabrication Solution

Based on our deep understanding of fabrication technologies, two decades of R&D of fabrication solution, and our practical experience, our company specializes in providing pipe spool lean fabrication one stop solution. We can design customer’s whole fabrication workshop even their fabrication plant according to customer's project workload and workshop conditions, etc. All of the designs aim at improving production efficiency, ensuring fabrication quality, and maximizing customer's benefits. Our solution can not only reduce customer's costs, but also help them to improve management...

Storage Tank Construction Solution-null

Storage Tank Construction Solution

We began R&D of automatic tank welding machines from year 2001. Now we have different types of tank welding machines for Oil Storage Tank. LNG Tank or Tower. The automatic tank welding machines we developed conform to CE standard. Besides we also developed hydraulic jacking system for top-to-bottom tank construction. Now we have matured whole solutions & equipments for both bottom-to-top and-top-to-bottom tank construction. By our solution, we can help our customer to finish one tank body construction within one month...

Horizontal Shell Fabrication Solution-null

Horizontal Shell Fabrication Solution

Horizontal tank shell is rolled from a steel plate with approximate length 3M. In our design we suggest 3M length sections can be fitted-up to a 12M length shell. And the 12M shell can be extended to required length. We integrated advanced and high efficient fabrication technology such as tandem welding and multi-wire welding into our design, designed machines suitable for different seams welding. Such whole planning and design has been implemented in the offshore fabrication base of CNPC. Our horizontal tank shell fabrication solution covers plate cutting, plate edge milling, shot blasting and painting, plate rolling, longitudinal seam welding, shell fitting-up, pretreatment, circumferential seam welding, shell extension; and non-destructive testing. Our offshore pipe pile/pipe rack fabrication capability suitable for pile rack diameter range from 500mm to 5000mm...

Pipeline Double Joining Solution-null

Pipeline Double Joining Solution

NAEC Pipeline Double Joining One Stop Solution adopts modular design which consist of multiple pipeline beveling stations, pipeline fitting-up and joining stations, and pipeline welding stations. It integrates with roller-bed type conveying system to reduce the dependence of on-site crane equipment. Compared with traditional pipeline construction method, nearly 1/2 welding joints can be fabricated by our Pipeline Double Joining One Stop Solution in advance and then other 1/2 welding joints will be done onsite by all-position welding method. Then the welding quality can be guaranteed. It's also easy to repair...

Intelligent Workshop Solution-

Intelligent Workshop Solution

Lean fabrication intelligent workshop is mainly consisted of three core parts, which are lean fabrication management system, lean fabrication design system and lean fabrication production system...

Intelligent Workshop Management System-

Intelligent Workshop Management System

Intelligence serves production, digital drives lean fabrication. The intelligent workshop established by NAEC, is the deep integration and innovation of advanced fabrication technology, information technology and communication technology under the workshop scene, which can improve the effective workshop output, and reduce the fabrication cost. Relied on the advanced technologies including Digital Twin, 5G+AR, Big Data, Artificial Intelligence, Internet of Things, Cloud Computing and Edge Computing etc., we provide digital one-stop solutions which set lean management as core concept to intelligent manufacturing industry such as energy engineering and construction machinery etc., provide intelligent workshop one-stop proposal, intelligent workshop management system and customized management system.

Intelligent Logistic System-

Intelligent Logistic System

Intelligence serves production, digital drives lean fabrication. The intelligent workshop established by NAEC, is the deep integration and innovation of advanced fabrication technology, information technology and communication technology under the workshop scene, which can improve the effective workshop output, and reduce the fabrication cost. Relied on the advanced technologies including Digital Twin, 5G+AR, Big Data, Artificial Intelligence, Internet of Things, Cloud Computing and Edge Computing etc., we provide digital one-stop solutions which set lean management as core concept to intelligent manufacturing industry such as energy engineering and construction machinery etc., provide intelligent workshop one-stop proposal, intelligent workshop management system and customized management system.

Intelligent Manufacturing丨Flexible Automated Excavator Solution-

Intelligent Manufacturing丨Flexible Automated Excavator Solution

Amid the wave of intelligent upgrades in the manufacturing industry, the traditional construction machinery sector is undergoing a profound transformation. As the most representative product in the construction machinery industry, excavators feature ...

lntelligent Pipe Spool Lean Fabrication Solution-null

lntelligent Pipe Spool Lean Fabrication Solution

Based on our deep understanding of fabrication technologies, two decades of R&D of fabrication solution, and our practical experience, our company specializes in providing pipe spool lean fabrication one stop solution. We can design customer’s whole fabrication workshop even their fabrication plant according to customer's project workload and workshop conditions, etc. All of the designs aim at improving production efficiency, ensuring fabrication quality, and maximizing customer's benefits. Our solution can not only reduce customer's costs, but also help them to improve management...

Storage Tank Construction Solution-null

Storage Tank Construction Solution

We began R&D of automatic tank welding machines from year 2001. Now we have different types of tank welding machines for Oil Storage Tank. LNG Tank or Tower. The automatic tank welding machines we developed conform to CE standard. Besides we also developed hydraulic jacking system for top-to-bottom tank construction. Now we have matured whole solutions & equipments for both bottom-to-top and-top-to-bottom tank construction. By our solution, we can help our customer to finish one tank body construction within one month...

Horizontal Shell Fabrication Solution-null

Horizontal Shell Fabrication Solution

Horizontal tank shell is rolled from a steel plate with approximate length 3M. In our design we suggest 3M length sections can be fitted-up to a 12M length shell. And the 12M shell can be extended to required length. We integrated advanced and high efficient fabrication technology such as tandem welding and multi-wire welding into our design, designed machines suitable for different seams welding. Such whole planning and design has been implemented in the offshore fabrication base of CNPC. Our horizontal tank shell fabrication solution covers plate cutting, plate edge milling, shot blasting and painting, plate rolling, longitudinal seam welding, shell fitting-up, pretreatment, circumferential seam welding, shell extension; and non-destructive testing. Our offshore pipe pile/pipe rack fabrication capability suitable for pile rack diameter range from 500mm to 5000mm...

Pipeline Double Joining Solution-null

Pipeline Double Joining Solution

NAEC Pipeline Double Joining One Stop Solution adopts modular design which consist of multiple pipeline beveling stations, pipeline fitting-up and joining stations, and pipeline welding stations. It integrates with roller-bed type conveying system to reduce the dependence of on-site crane equipment. Compared with traditional pipeline construction method, nearly 1/2 welding joints can be fabricated by our Pipeline Double Joining One Stop Solution in advance and then other 1/2 welding joints will be done onsite by all-position welding method. Then the welding quality can be guaranteed. It's also easy to repair...

Intelligent Workshop Solution-

Intelligent Workshop Solution

Lean fabrication intelligent workshop is mainly consisted of three core parts, which are lean fabrication management system, lean fabrication design system and lean fabrication production system...

TYPICAL CASES

NEWS

Brand New Cooperation Chapter —— NAEC & Penta Laser-

Brand New Cooperation Chapter —— NAEC & Penta Laser

Nanjing Auto Electric Co., Ltd. (NAEC Group) and Pentium Laser (Wenzhou) Co., Ltd. (Penta Laser) formally signed a strategic cooperation agreement. Mr. Zhu Xiaoming, Chairman of NAEC Group, and Martino Burlamacchi, Chairman of Pentium Laser (Wenzhou)...

Customer Visiting | NAEC——Your Lean Fabrication Partner-

Customer Visiting | NAEC——Your Lean Fabrication Partner

Recently, Russian customers visited NAEC factory for a field trip, and NAEC warmly welcomed the visiting customers. Both of us had in-depth exchanges and discussions on pipe spool fabrication production lines, welding equipment and welding robots! In...

VINAMAC EXPO 2023, We are Here!-

VINAMAC EXPO 2023, We are Here!

This week (November 15-17), NAEC made its appearance at VINAMAC EXPO 2023. As a metal intelligent lean prefabrication service provider, during the exhibition, NAEC demonstrated our advanced technology, efficient digital equipment and lean intelligent...

NAEC Intelligent Assembly Production Line with High Efficiency-

NAEC Intelligent Assembly Production Line with High Efficiency

With the continuous development and progress of digitalization and IOT technology, industrial automation will be further promoted. Facing the disadvantages of traditional assembly, intelligent assembly production line came into being, which is an eff...

NAEC Intelligent Logistics I How to Choose the Right AGV?-

NAEC Intelligent Logistics I How to Choose the Right AGV?

With the development of intelligent manufacturing, the intelligentization of logistics industry has become an inevitable trend. Among them, AGV is an indispensable part of the automated logistics system, and it is one of the key equipment of flexible...

NAEC Lean Intelligent Manufacturing Solution for Mining Truck-

NAEC Lean Intelligent Manufacturing Solution for Mining Truck

Under the promotion of "Industry 4.0", intelligent automatic welding production line has become one of the hot spots and trends in the manufacturing field. Intelligent and automation technology is more and more widely used in the welding production l...

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards-

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabiliti...

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards-

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabiliti...

NAEC Lean Pipe Spool Fabrication Management Platform-

NAEC Lean Pipe Spool Fabrication Management Platform

NAEC Lean Pipe Spool Fabrication Management Platform In the field of pipe spool fabrication for energy engineering, intensified market competition and rising cost pressures continue to squeeze the survival space of enterprises. The industry has long ...

Steel Structure Intelligent Production Line: Breaking the Shackles of Capacity Constraints, Setting a New Benchmark for Industry Efficiency-

Steel Structure Intelligent Production Line: Breaking the Shackles of Capacity Constraints, Setting a New Benchmark for Industry Efficiency

Intelligent Production Line Solution for Steel Structures Lean Intelligent Manufacturing Solution Provider In the construction and engineering sectors, steel structures are widely adopted for their high strength, lightweight properties, and rapid con...

Fully Automated End-to-End Solution丨Hydraulic Cylinder Welding Workstation-

Fully Automated End-to-End Solution丨Hydraulic Cylinder Welding Workstation

NAEC In the wave of global intelligent manufacturing, efficient, precise, and flexible automated production equipment has become the core driving force for industrial transformation and upgrading. Addressing the challenges of complex welding processe...

Industrial Production Line Digital Twin Solution — Full-Process Intelligent Management-

Industrial Production Line Digital Twin Solution — Full-Process Intelligent Management

NAEC Intelligent Digital As Industry 4.0 reshapes global manufacturing, many traditional enterprises face challenges such as non-transparent processes, stagnant efficiency, and high management costs. Digital Twin technology is emerging as a core engi...

NAEC Intelligent Production Line Case | Wheel Press Circumferential Seam Digital Twin-

NAEC Intelligent Production Line Case | Wheel Press Circumferential Seam Digital Twin

ONE Project Overview NAEC developed the “Wheel Press Circumferential Seam Digital Twin Smart Production Line Project” for a heavy industry group. As a key project in the group’s digital transformation, it connects the MES and LES systems, integrating...

RGV Application in Automated Storage & Retrieval Systems (AS/RS)-

RGV Application in Automated Storage & Retrieval Systems (AS/RS)

RGV (Rail Guided Vehicle) is an intelligent automated guided vehicle widely used in AS/RS. It features high speed, reliability, and low cost. Equipped with automatic navigation and sensing devices, the RGV can autonomously follow preset paths to tran...

Lean Intelligent Manufacturing Solutions for Mining Trucks, Achieving Intelligence in Every Process Step!-

Lean Intelligent Manufacturing Solutions for Mining Trucks, Achieving Intelligence in Every Process Step!

NAEC Lean Intelligent Manufacturing N A E C Driven by the initiatives of "Industry 4.0" and "Made in China 2025," intelligent and automated welding production lines have become one of the hottest trends and focal points in the manufacturing sector. T...

Innovation Breakthrough! NAEC Builds High-Efficiency Lean Pipe Spool Fabrication Production Line for Nuclear Power Project-

Innovation Breakthrough! NAEC Builds High-Efficiency Lean Pipe Spool Fabrication Production Line for Nuclear Power Project

In nuclear power construction, enhancing the intelligence and efficiency of the p ipe s pool f abrication process is of paramount importance. With nearly 30 years of industry service experience and proven capabilities in implementing intelligent co...

Intelligent Manufacturing丨Flexible Automated Excavator Solution-

Intelligent Manufacturing丨Flexible Automated Excavator Solution

Amid the wave of intelligent upgrades in the manufacturing industry, the traditional construction machinery sector is undergoing a profound transformation. As the most representative product in the construction machinery industry, excavators feature ...

WMS System: Exploring AI and Big Data Empowerment in Warehouse Management-

WMS System: Exploring AI and Big Data Empowerment in Warehouse Management

In the wave of digital transformation, AI technology is reshaping the field of warehouse management at an astonishing pace. Traditional Warehouse Management Systems (WMS), as the "data stewards" of enterprises, are responsible for recording inventory...

ChatWelding: AI Welding Knowledge Base Model Developed by NAEC-

ChatWelding: AI Welding Knowledge Base Model Developed by NAEC

CHATWELDING Welding Knowledge Base Model As a subsidiary of NAEC Group, NAEC Intelligent Digital is committed to the intelligent transformation and digital transformation of metal engineering field. Through more than 20 years of R&D iteration, platfo...

NAEC Shined at the 21st China Construction Machinery Summit!-

NAEC Shined at the 21st China Construction Machinery Summit!

NAEC, as a leading provider of lean manufacturing solutions in global metal engineering, was invited to attend the 21st China Construction Machinery Development Summit and China Construction Machinery Smart Manufacturing Summit. We showcased our prod...

NAEC Co-Organized this Major Conference in Nanjing-

NAEC Co-Organized this Major Conference in Nanjing

The 2nd Annual Conference on New Equipment and Technologies in Shipbuilding was convened in Nanjing in 2024, where representatives from various maritime industry gathered. With over 200 participants, including representatives from leading marine engi...

NAEC Lean Pipe Spool Fabrication Management System-

NAEC Lean Pipe Spool Fabrication Management System

NAEC Lean Pipe Spool Fabrication Management System, tailored for the pipeline construction industry, The management system offers fine-grained production control throughout the entire lifecycle of pipe spool fabrication, including factory prefabricat...

NAEC Intelligent Logistics | Application Advantages of RGV-

NAEC Intelligent Logistics | Application Advantages of RGV

RGV (Rail Guided Vehicle) is a type of rail-guided, electrically powered transport vehicle commonly used in factories. Also known as an RGV rail-guided automated transport vehicle, it is widely applied in industrial automation production lines and lo...

NAEC Global Annual Celebration —— Journey Onward, Reach Beyond!-

NAEC Global Annual Celebration —— Journey Onward, Reach Beyond!

Moving forward together to embark on a new journey! On February 3, 2024, the 2024 Global Annual Meeting of NAEC Group was grandly held. Mr. Zhu Xiaoming, Chairman of NAEC Group, and Ms. Xie Ying, President of NAEC Group, gathered together with leader...

Congratulations!New Year, New Project, New Beginnings!-

Congratulations!New Year, New Project, New Beginnings!

Good news is here, NAEC has obtained a new project for metal intelligent fabrication production line from our Tunisian customer. This week, we welcomed a site visit from the Tunisian customer for in-depth exchanges and discussions on metal lean fabri...

STEELFAB 2024, NAEC Showtime!-

STEELFAB 2024, NAEC Showtime!

From January 8th to 11th, the four-day STEELFAB 2024 kicked off at the Expo Centre Sharjah, Sharjah, UAE. Top domestic and international industry experts and well-known companies gathered here, and NAEC, as one of the exhibitors at this exhibition, m...

NAEC Lean Intelligent Manufacturing Solution for Steel Structure-

NAEC Lean Intelligent Manufacturing Solution for Steel Structure

NAEC Intelligent Painting Production Line with High Automation!-

NAEC Intelligent Painting Production Line with High Automation!

NAEC "Intelligent Painting Production Line" is an important breakthrough for NAEC to build a green intelligent manufacturing factory with the Internet and digital empowerment, help the transformation and upgrading of the manufacturing industry, incre...

Factory Modeling —— Lean Manufacturing Management Cornerstone!-

Factory Modeling —— Lean Manufacturing Management Cornerstone!

NAEC Smart Digital MOM ( Manufacturing Operation Management System ) is the key to the optimization and integration of smart factories. It connects all departments and links of enterprises, connects the whole manufacturing life cycle and supply chain...

NAEC Successful FAT of Energy Fabrication Projects!-

NAEC Successful FAT of Energy Fabrication Projects!

Recently, the FAT work of storage tank construction project in the South American and the pipe cutting production system in Central Asia have been organized and completed in an orderly manner. Each project all took one day to complete the pe...

Brand New Cooperation Chapter —— NAEC & Penta Laser-

Brand New Cooperation Chapter —— NAEC & Penta Laser

Nanjing Auto Electric Co., Ltd. (NAEC Group) and Pentium Laser (Wenzhou) Co., Ltd. (Penta Laser) formally signed a strategic cooperation agreement. Mr. Zhu Xiaoming, Chairman of NAEC Group, and Martino Burlamacchi, Chairman of Pentium Laser (Wenzhou)...

Customer Visiting | NAEC——Your Lean Fabrication Partner-

Customer Visiting | NAEC——Your Lean Fabrication Partner

Recently, Russian customers visited NAEC factory for a field trip, and NAEC warmly welcomed the visiting customers. Both of us had in-depth exchanges and discussions on pipe spool fabrication production lines, welding equipment and welding robots! In...

VINAMAC EXPO 2023, We are Here!-

VINAMAC EXPO 2023, We are Here!

This week (November 15-17), NAEC made its appearance at VINAMAC EXPO 2023. As a metal intelligent lean prefabrication service provider, during the exhibition, NAEC demonstrated our advanced technology, efficient digital equipment and lean intelligent...

NAEC Intelligent Assembly Production Line with High Efficiency-

NAEC Intelligent Assembly Production Line with High Efficiency

With the continuous development and progress of digitalization and IOT technology, industrial automation will be further promoted. Facing the disadvantages of traditional assembly, intelligent assembly production line came into being, which is an eff...

NAEC Intelligent Logistics I How to Choose the Right AGV?-

NAEC Intelligent Logistics I How to Choose the Right AGV?

With the development of intelligent manufacturing, the intelligentization of logistics industry has become an inevitable trend. Among them, AGV is an indispensable part of the automated logistics system, and it is one of the key equipment of flexible...

NAEC Lean Intelligent Manufacturing Solution for Mining Truck-

NAEC Lean Intelligent Manufacturing Solution for Mining Truck

Under the promotion of "Industry 4.0", intelligent automatic welding production line has become one of the hot spots and trends in the manufacturing field. Intelligent and automation technology is more and more widely used in the welding production l...

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards-

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabiliti...

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards-

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabiliti...

NAEC Lean Pipe Spool Fabrication Management Platform-

NAEC Lean Pipe Spool Fabrication Management Platform

NAEC Lean Pipe Spool Fabrication Management Platform In the field of pipe spool fabrication for energy engineering, intensified market competition and rising cost pressures continue to squeeze the survival space of enterprises. The industry has long ...

Steel Structure Intelligent Production Line: Breaking the Shackles of Capacity Constraints, Setting a New Benchmark for Industry Efficiency-

Steel Structure Intelligent Production Line: Breaking the Shackles of Capacity Constraints, Setting a New Benchmark for Industry Efficiency

Intelligent Production Line Solution for Steel Structures Lean Intelligent Manufacturing Solution Provider In the construction and engineering sectors, steel structures are widely adopted for their high strength, lightweight properties, and rapid con...

Fully Automated End-to-End Solution丨Hydraulic Cylinder Welding Workstation-

Fully Automated End-to-End Solution丨Hydraulic Cylinder Welding Workstation

NAEC In the wave of global intelligent manufacturing, efficient, precise, and flexible automated production equipment has become the core driving force for industrial transformation and upgrading. Addressing the challenges of complex welding processe...

Industrial Production Line Digital Twin Solution — Full-Process Intelligent Management-

Industrial Production Line Digital Twin Solution — Full-Process Intelligent Management

NAEC Intelligent Digital As Industry 4.0 reshapes global manufacturing, many traditional enterprises face challenges such as non-transparent processes, stagnant efficiency, and high management costs. Digital Twin technology is emerging as a core engi...